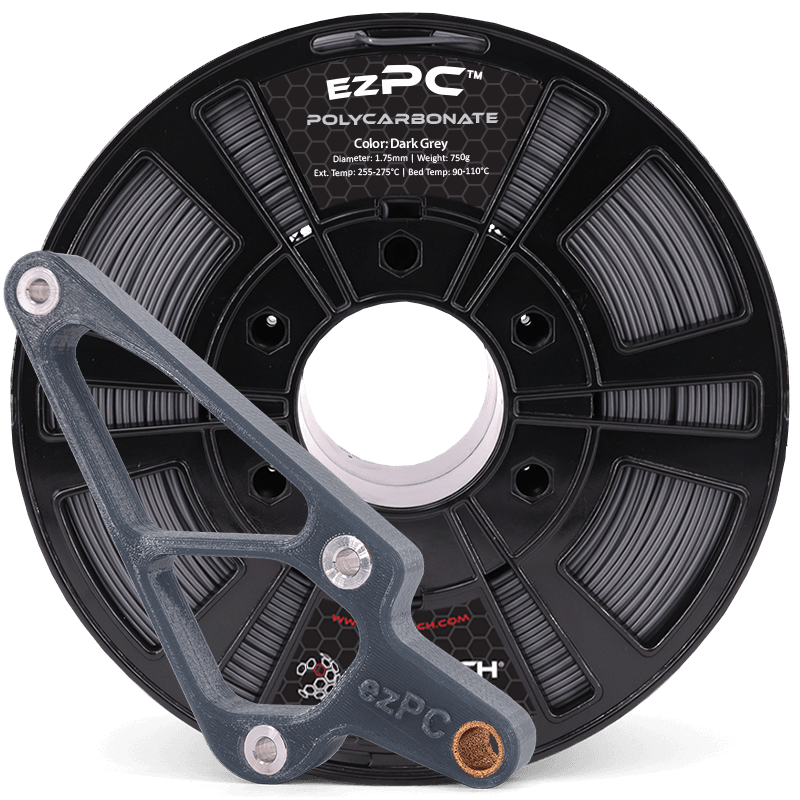

ezPC Polycarbonate

We absolutely love printing ezPC! This polymer was developed specifically for 3D printing functional prototypes and end-use parts. It was formulated to allow for ease of printing coupled with exceptional mechanical and thermal properties.

ezPC Polycarbonate is an excellent choice for printing parts that would ordinarily fail when using standard materials such as PLA, PETG, or ABS. We consider this an excellent bridge in performance between these lower performance materials and higher priced materials such as Ultem or PEEK.

MADE IN THE USA

We manufacture all of our filaments in our 68,000 ft² manufacturing facility (located in Grand Rapids, Michigan) using state-of-the-art equipment and processes. Our goal continues to be to make the most innovative filaments on the market – targeting difficult end-use applications.

Print Recommendations

Have a Great Profile? Share It With the Community