ESD-Safe Filament

Electrostatic discharge-safe, or ESD-safe, materials are essential for protecting sensitive electronics, ensuring industry compliance, and enhancing reliability across various sectors. They safeguard mission-critical components in industries like aerospace, defense, and automotive while reducing risks in high-stakes environments such as oil and gas.

Shop ESD-Safe Filament

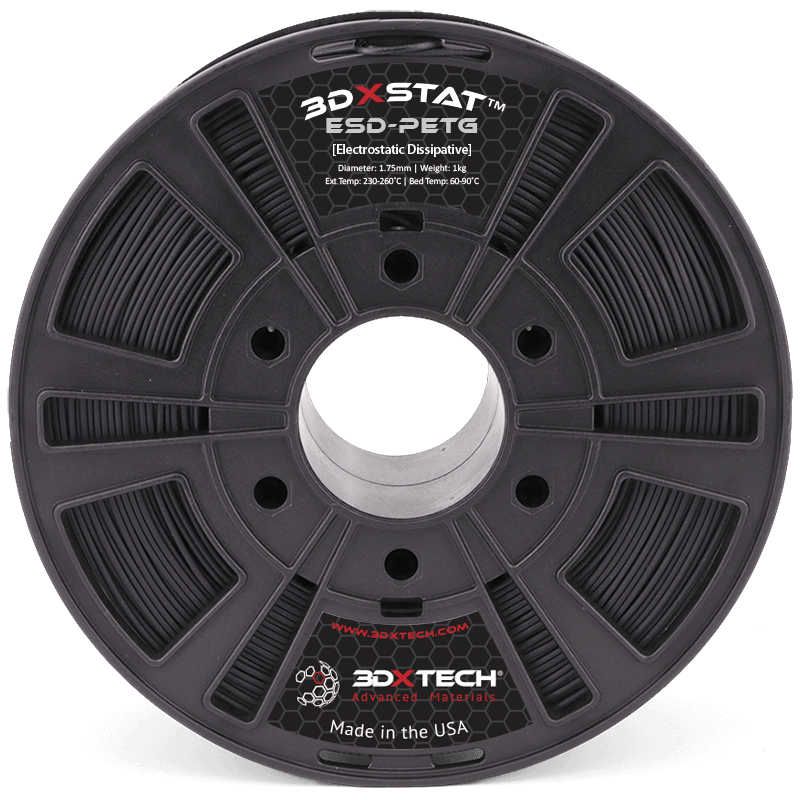

We have the largest selection of ESD-Safe 3D printing filaments on the market. Our compounds are made using cutting-edge multi-wall carbon nanotube [CNT] technology, state of the art compounding technology, and precision extrusion processes.

Benefits of ESD-Safe Filament

ESD-safe filament is used in 3D printing to create objects that prevent or reduce the risk of electrostatic discharge (ESD). Electrostatic discharge can damage sensitive electronic components and circuits, so using ESD-safe materials is crucial in environments where electronic components are handled or assembled.

Protects Sensitive Electronics

ESD-safe filament helps in manufacturing components that prevent static electricity from building up, thereby protecting sensitive electronic parts from static discharge damage.

Prevents Static Build-up

ESD-safe materials are designed to dissipate static charges rather than allow them to accumulate, reducing the risk of accidental discharges that could harm electronic devices.

Improves Safety in Electronic Assembly

In environments where electronics are assembled or tested, using ESD-safe components reduces the risk of static-related damage, contributing to overall safety and reliability.

Versatility in Applications

ESD-safe filament can be used in a wide range of applications, including custom enclosures, tool holders, and work surfaces, making it versatile for various needs in an ESD-sensitive environment.

Applications

ESD-safe materials are crucial across industries for protecting sensitive electronics from electrostatic discharge, ensuring compliance with industry standards, and improving overall reliability. In sectors like aerospace, defense, and automotive, they safeguard mission-critical components and enhance quality control. These materials also reduce risks in high-stakes environments, such as oil and gas, and ensure the integrity of medical devices and DIY electronics.

Static-Free Tooling

Tools and fixtures that help in the assembly and testing of electronic components.

Protective Enclosures

Custom enclosures for sensitive machinery controls and electronic systems to prevent static damage.

Instrument Panels

ESD-safe housings for avionics and control panels that protect sensitive electronics from static discharge.

Custom Mounts and Brackets

Static-safe components for holding and securing electronic systems in spacecraft and aircraft.

Equipment Cases

Static-protective cases and enclosures for communication devices and military electronics.

Control Panels

ESD-safe control panels and housings for sensitive defense electronics and instrumentation.

Component Holders

Static-free trays and organizers for storing and handling electronic components during assembly.

Test Equipment Enclosures

Protective enclosures for test and measurement equipment to prevent static damage during operation.

Sensor Housings

ESD-safe housings for automotive sensors and electronic control units (ECUs) to ensure reliable operation.

Custom Tooling

Static-free tools for automotive assembly and maintenance, reducing the risk of damage to electronic systems.

Instrument Enclosures

Protective cases for electronic instruments and sensors used in hazardous environments to prevent static discharge.

Equipment Mounts

ESD-safe mounts and brackets for securing sensitive electronic equipment in drilling and extraction machinery.

Device Housings

Static-free enclosures for medical devices and diagnostic equipment, ensuring they operate correctly and reliably.

Custom Medical Tools

ESD-safe tools used in the assembly and maintenance of medical equipment to prevent damage to sensitive electronics.

DIY Electronics Projects

Custom enclosures and mounts for hobbyist electronics projects to protect components from static damage.

3D Printed Test Fixtures

Static-safe fixtures and holders for testing and assembling electronic components in personal projects.