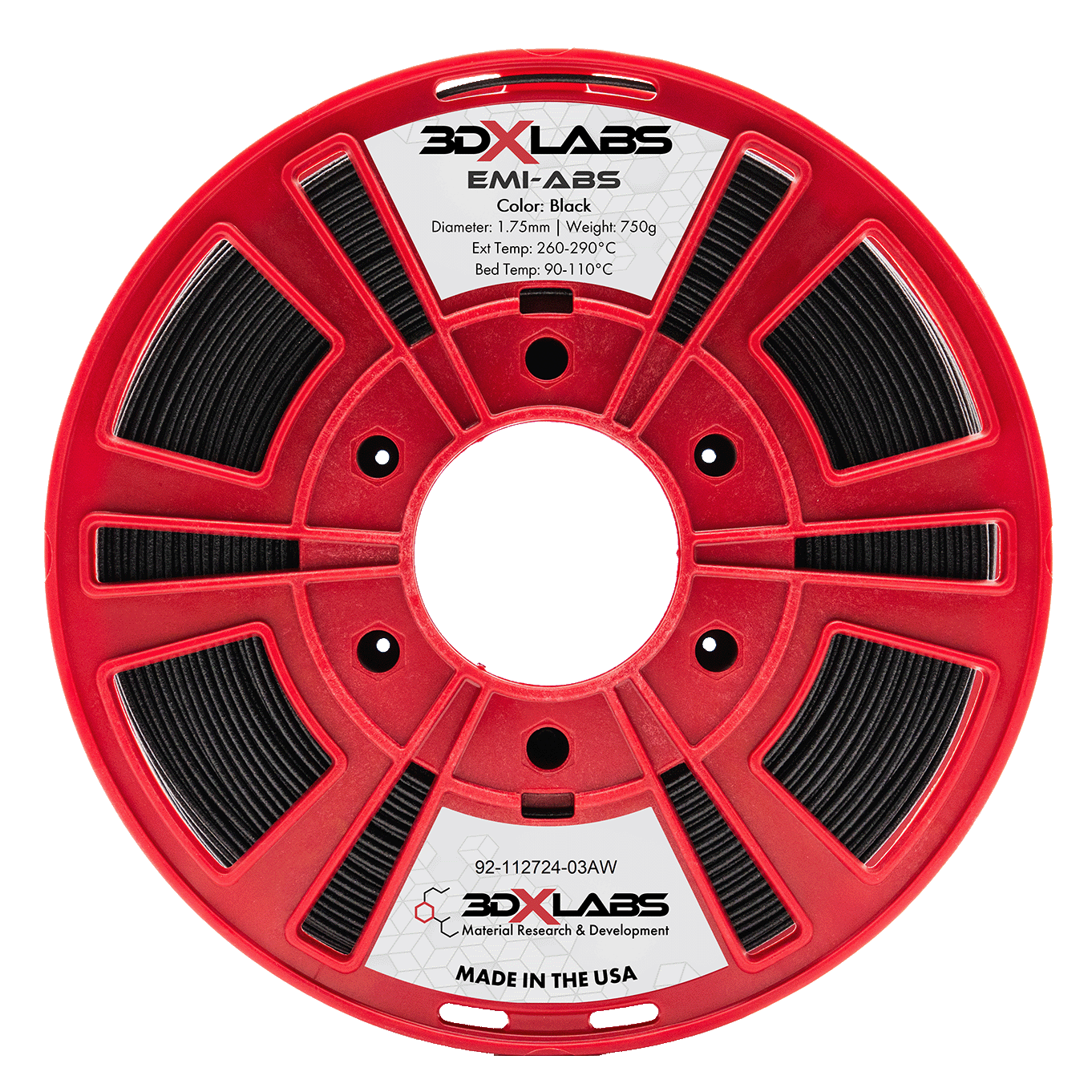

3DXLABS™ EMI-ABS

**3DXLABS R&D PRODUCT**

Be among the first to test our latest development: EMI-ABS, a cutting-edge, electrically conductive ABS blend engineered to provide EMI shielding performance in FDM 3D printing applications.

As part of our 3DXLabs R&D program, this material is available exclusively to our experienced users who want early access to experimental formulations and the opportunity to shape future products through direct feedback.

Key Features:

-

EMI Shielding Performance:

-

Near 0 dB shielding effectiveness below 500MHz

-

Begins increasing at 600MHz, with strong performance above 700MHz

-

Between 4 dB and 16 dB shielding effectiveness from 1GHz to 9GHz, depending on infill pattern and density

-

-

Printability:

-

Excellent layer adhesion and surface quality when printed on Bambu X1C (no heated chamber required)

-

Heated chamber recommended to maximize mechanical strength and finish

-

Minimal warping compared to standard unfilled ABS

-

-

Recommended Print Settings:

-

Nozzle Temp: 285°C

-

Bed Temp: 100°C

-

Min. Chamber Temp: 60°C

-

Speed: 100 mm/s

-

Nozzle Diameter: 0.40mm, Hardened Steel

- Min. Layer Height: 0.20mm

-

3DXLabs materials are experimental and offered in limited batches. If you’re a seasoned user who wants to be at the forefront of 3D printing innovation, this is your chance to try EMI-ABS and help shape its development.

MADE IN THE USA

We manufacture all of our filaments in our 68,000 ft² manufacturing facility (located in Grand Rapids, Michigan) using state-of-the-art equipment and processes. Our goal continues to be to make the most innovative filaments on the market – targeting difficult end-use applications.

Have a Great Profile? Share It With the Community