3D Printing End-Use Parts

On Demand Production With More Possibilities.

By leveraging the strengths of additive manufacturing, companies can create innovative, efficient, and tailored end-use parts that meet the evolving needs of their industries.

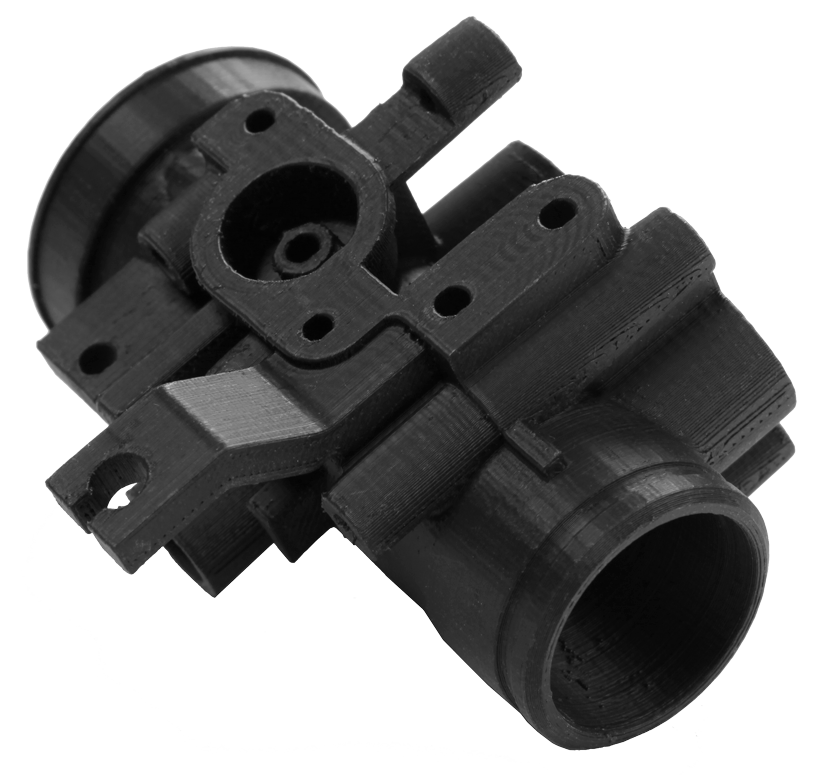

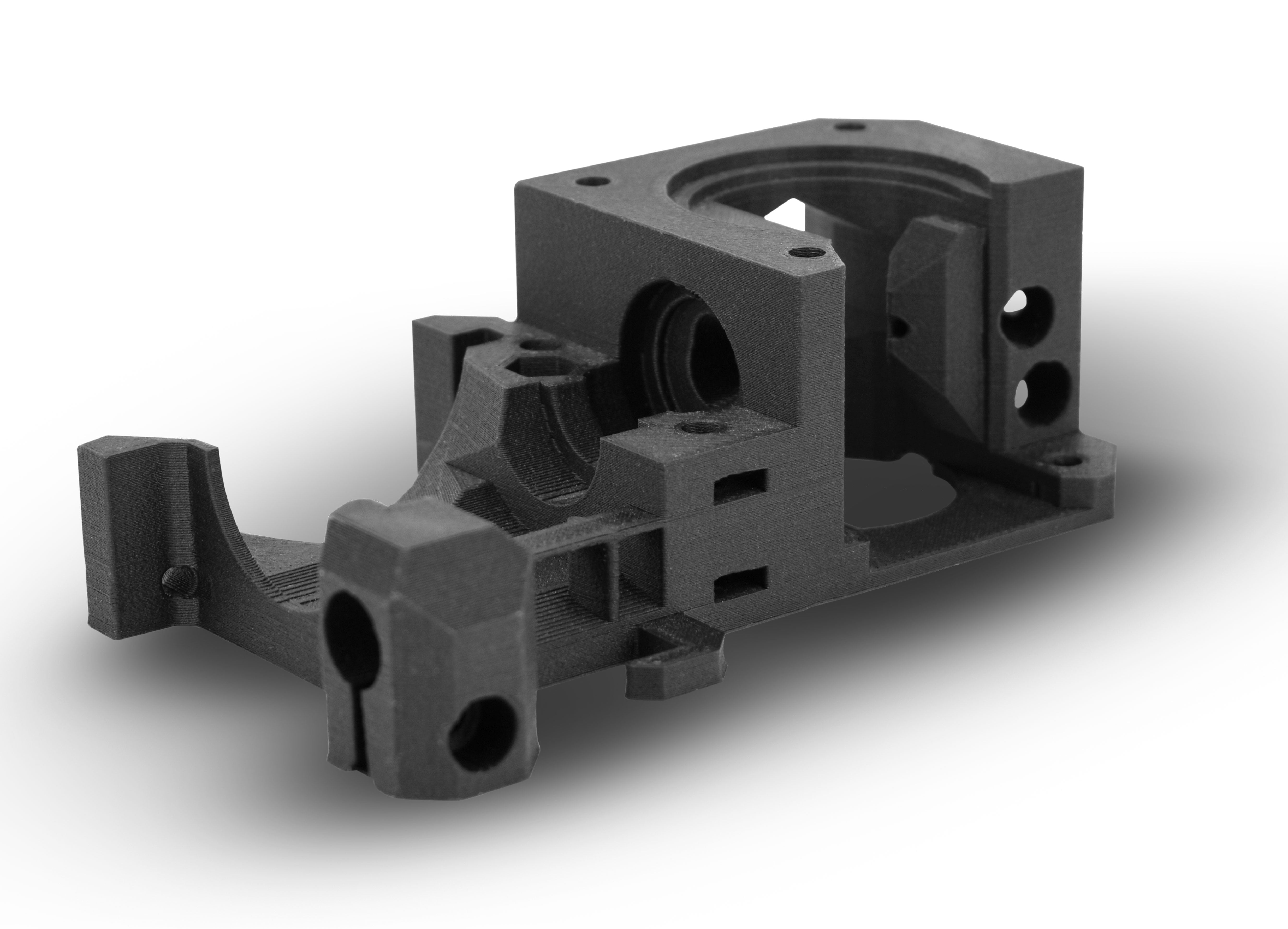

Design Flexibility

Additive manufacturing allows for complex geometries and designs that traditional manufacturing processes may not accommodate, enabling lightweight structures and intricate details.

Reduce Lead Times

Significantly reduce the time from design to production, allowing for rapid prototyping and quicker response to market demands.

Customized Resistance

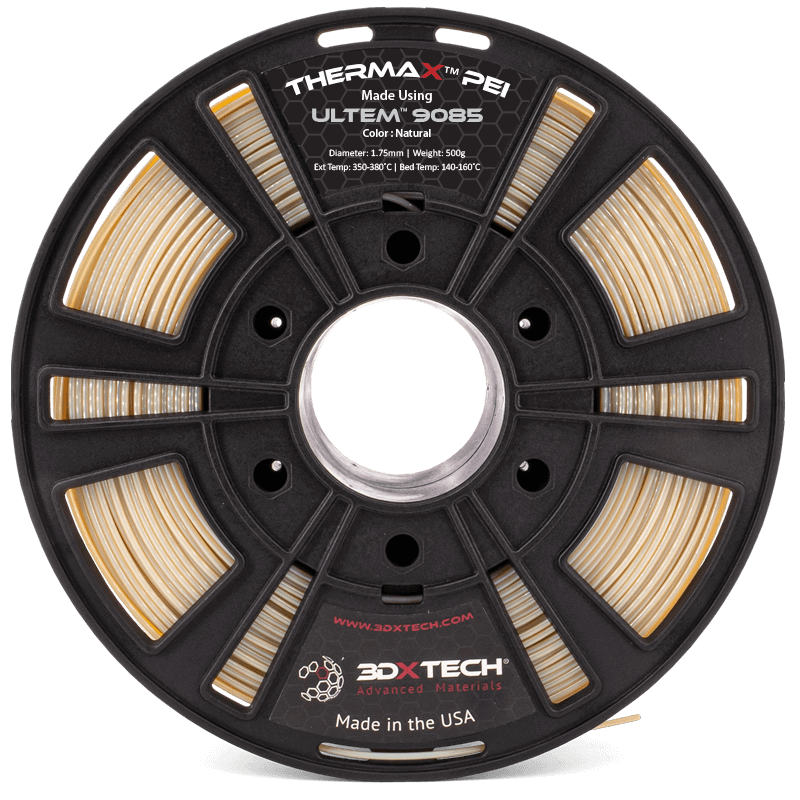

There are plenty of filament options available to tailor your end-use part to withstand specific environments, such as ESD-safe, flame retardant, high temperatures, and high friction.

Popular Applications of End-Use Parts

Brackets

Instrument Panels

Housing

High Temperature Resistant

Popular Filaments used for End-Use Parts

NEED STRATASYS COMPATIBLE FILAMENT?

Don't worry! We've got you covered.