ESD properties as a function of extruder temperature

3DXTech® is the leading supplier of ESD-Safe materials in the 3D printing market. We have developed the broadest portfolio of ESD-Safe materials - ranging from PLA up to PEKK. As such, we perform a great deal of testing on our materials on many different printers to understand how these materials print as well as how best to optimize the print settings to achieve parts to meet your specific needs.

Background: Prior to starting 3DX, I worked for several large resin suppliers (Solvay, DSM, Bayer) for over 20 years developing numerous materials and applications - including many that required ESD properties. We worked with the customer to create, optimize, and trouble shoot the processing of our materials. We found that the processing temperature of these materials (i.e., melt temp, mold temp) had a significant effect on the surface resistance of the molded part. The processing parameters of every part had to be optimized for a given material, part geometry, and tooling combination. Altering any of these would result in different surface resistance readings, but those related to temperature were critical.

Problem Investigated: We created a wide array of ESD-safe materials that are suitable to be printed on a variety of printers. As such, we offer general processing guidelines for our materials and consider these as "good starting points" for creating a print profile that works for your specific material/printer/part combination. We often get calls from customers indicating that they tried one of our ESD-Safe materials and the surface resistance was too high or too low and the part failed their testing. Knowing that melt temperature has a significant effect on these materials, we wanted to perform a study to underscore this temp/conductivity effect and create processing tips to be used by our customers to improve their printing experience.

Study Performed: We varied the extruder temperature throughout the range of recommended extruder settings to determine the effect of extruder temperature on surface resistance of a printed specimen.

- Test specimen: Square plaque with dimensions of 100 x 100 x 4mm, printed horizontally.

- Slice parameters: Solid infill, 0.04mm nozzle, 0.25mm layer, +/- 45 infill, 2 perimeter walls (inside/out).

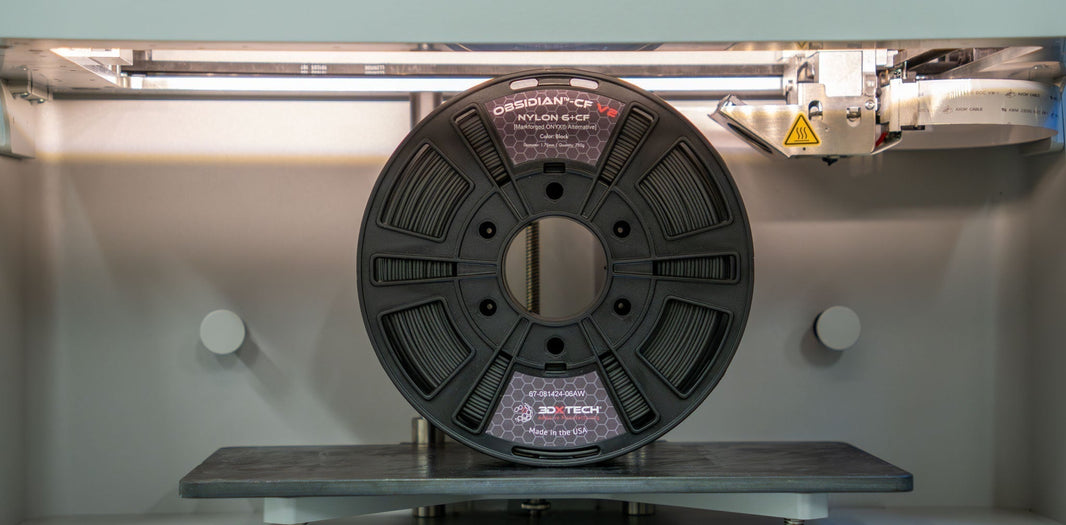

- Printer: Gearbox™ HT2 (more info on this printer can be found HERE).

- Test apparatus: Prostat® ESD test rig (PRS-812), concentric ring set. Measure the surface resistance with a legit ESD meter and not a multi-meter. The right tool will give you more reliable and repeatable results.

- Test frequency: 3 measurements at 10°C increments throughout the recommended extruder temp range of a given material.

Key learnings and tips for improved surface resistance on printed parts:

- Changes in extruder temperature will effect surface resistance. As with other plastic processing methods that we have used in the past, we found that the surface resistance of the 3D printed part can be 'tuned' by altering the extruder temperature of the printer during printing. Printing with a higher extruder temperature results in a more conductive surface = lower surface resistance. The measured change in the surface resistance was different for each material, but this effect was consistent across all materials tested. Every printer will be different, but the general theme is clear: higher extruder temps = higher surface conductivity.

- Tight raster spacing improves surface conductivity on horizontal surfaces. The closer to each other you can get the rasters, the higher the overall conductivity will be for the part.

- Vertical wall conductivity was lower than horizontal wall conductivity. We tested plaques built vertically and found that the surface conductivity of vertical walls were typically about 1 magnitude of order less conductive than similarly printed horizontal plaque surfaces.

Test Results of 3DXSTAT™ ESD-Safe 3D Filaments

Each data point ("X") is an average of 3 tests at a given extruder temperature.